Sensors for batteries

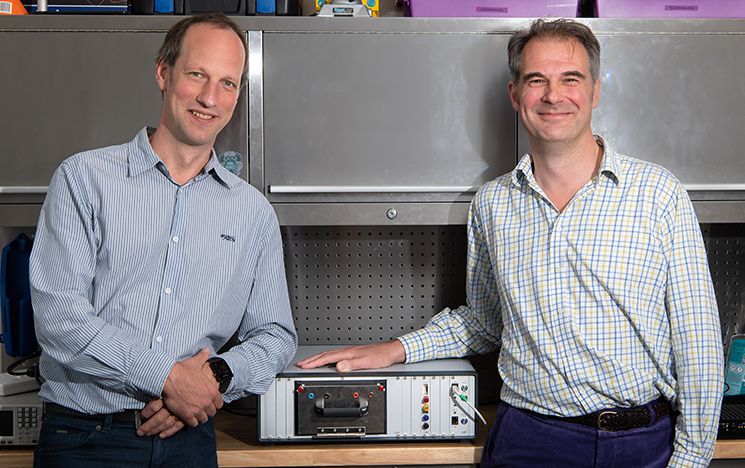

In collaboration with our industry partner cdo2, we have developed real-time current density imaging systems using classical and quantum sensors to diagnose electric vehicle (EV) batteries for a sustainable future. These systems are used to measure the current flow inside EV batteries to estimate their charge, health and detect faults early. In a fast growing EV market with government targets to stop the production of new diesel and petrol cars, this technology has potential to significantly improve both safety and durability of the batteries. The Battery Current Density Analyser is commercially available from our industry partner CDO2 born out of our collaborative research.

With this technology, it will be possible to do a quick non-invasive battery check which is useful for anyone needing to check the state of health of a EV battery. The case of the Boeing 787 Dreamliner, which saw disastrous fires breaking out stemming from its batteries, demonstrates the importance of being able to tell whether batteries are operating safely.

By using quantum sensors to give an accurate state of a battery’s health, rather than relying on a calculated estimate as happens now, it means that fewer EV batteries will be discarded unnecessarily or prematurely. It will make EV batteries more recyclable with the working parts of the battery pack being retained.

The quantum sensors can also test the health of electric batteries streamlining the battery development process. Normally, electric batteries are left to develop at a warm temperature and are assumed to be ready after several weeks. With the new quantum sensors, the batteries can be tested for their readiness in real-time, potentially speeding the production process from weeks to days. This means they’ll be useable more quickly, and that more batteries can be created in the meantime saving factory space and energy costs.