Thermofluids

We're globally renowned for excellence in the field of gas turbine technology with emphasis on gas turbine internal or secondary air systems, gas-path aerodynamics and component heat transfer and the modelling of flow and combustion.

Research aims

Our current research covers a broad range of key areas including cooling and sealing systems in advanced gas turbines, low temperature power cycles and waste heat recovery technologies, alongside domestic and consumer thermal management and combines theoretical, numerical and experimental aspects.

Research areas

Find out more about our research areas:

- Pressure gain combustion by shock-flame interaction

- Better turbines: Thermal creation and differential work

- Boundary layer transition

- Axial compressors

- Rotating cavities

- Rotor-stator cavity and rim-seals

Pressure gain combustion by shock-flame interaction

Weak shockwaves at 250 Hz are injected into the combustion chamber which is running steadily otherwise. Unsteady pressure transducers show that as the shockwaves get stronger the combustion efficiency rises.” PROFESSOR mARTIN g. rose

Professor of Mechanical Engineering

In steady flow gas turbines the total pressure across the combustion chamber can typically fall by about 5%. This signifies a considerable reduction in thermal efficiency of the engine. It is well known that isochoric (constant volume) combustion could lead to a significant increase in thermal efficiency. However, the difficulty is that isochoric combustion must occur under unsteady conditions, while gas turbines are steady flow devices.

The worlds first gas turbines used constant volume combustion chambers with valves to fill and empty them. In EMERC, we are addressing a different possibility using shock waves which can cause acceleration of the combustion process by the Richtmayer–Meshkov instability. The non-uniform density associated with combustion interacts with the pressure rise of the shock creating strong vorticity. Flow structures (funnels) form which increase the flame area rapidly. The increased heat release causes a rapid pressure rise. Borisov has demonstrated that a weak shock wave (Mach = 1.1) can accelerate the combustion right up to detonation.

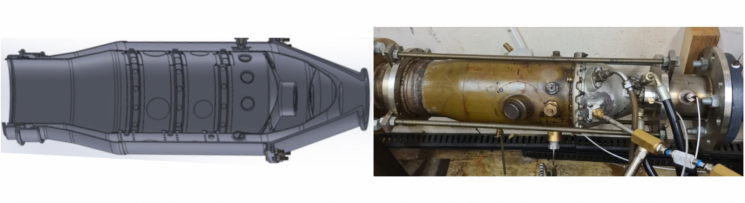

We have modified our Dart combustion rig by introducing a series of shockwaves. A solenoid valve connected to a pressure vessel at 6 bar is used to create a chain of shockwaves at 250 Hz. So far, we have demonstrated the acceleration of combustion and found that as the shockwaves get stronger the combustion efficiency increases.

Faculty

Better turbines: Thermal creation and differential work

Two mechanisms within the flow-field of axial turbines have been recently explored: thermal creation and differential work. Both have the potential to boost turbine efficiency.” pROFESSOR mARTIN G. rose

Professor of Mechanical Engineering

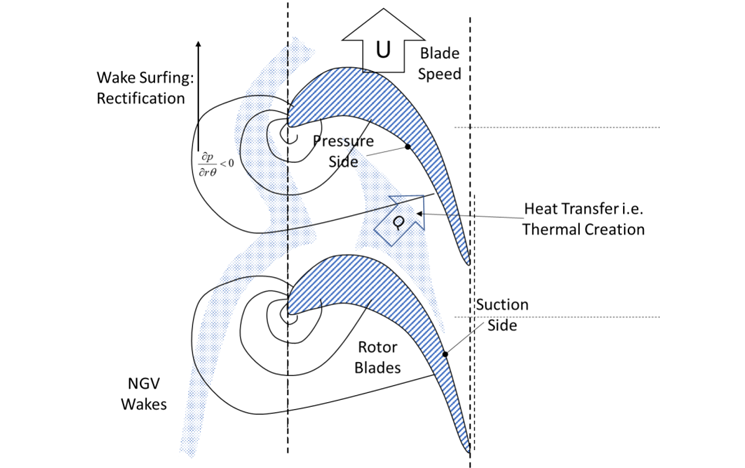

Turbine aerofoils create wakes due to friction. Such wakes subsequently mix out causing entropy rise and lower efficiency. The unsteady work process in a turbine tends to make the flow more uniform, avoiding entropy rise and boosting efficiency, and this is known as “differential work”. The flow field inside the turbine also has non-uniform temperatures leading to turbulent heat transfer. If heat is transferred from a hot region of low pressure towards a cooler region at higher pressure then the mechanical work potential of the turbine increases. This process has been named “thermal creation”.

Using high fidelity Computational Fluid Dynamics in particular, Large Eddy Simulation, it is possible to evaluate the strength of these phenomena. These are assumed to be a function of the aerodynamic design. High-pressure turbines have to be cooled and this will have a strong influence on the heat transfer and in turn thermal creation. In low-pressure turbines ,very little cooling is required and wakes are generally hot. Differential work also increases the wake temperature so heat loss to regions of higher static pressure appears to be likely, leading to performance improvement due to thermal creation.

Faculty

Boundary layer transition

The transition mechanism from laminar to turbulent flow remains poorly understood. Transition has an important effect on the performance of fluid machines such as turbines and compressors. Understanding and controlling it will help to reduce aerodynamic losses and make the machines environmentally friendly.” DR Vasudevan KANJIRAKKAD

Senior Lecturer in Experimental Thermofluid Mechanics

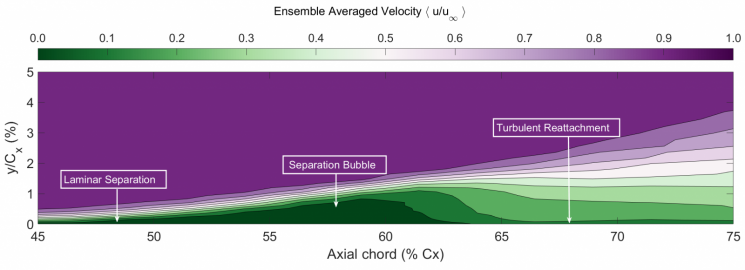

Gas turbine blade surfaces are known to have large regions of laminar and transitional flow. The significance of transition is particularly important under low Reynolds number operation. Due to the low frictional losses associated with laminar flow, delaying transition is advantageous. However, under adverse pressure gradient conditions, the laminar flow can separate and increase profile losses if open separation persists.

Our research looks at the phenomenon of separated boundary layer transition on the surface of an axial compressor blade under steady and unsteady (wake) inlet conditions. Detailed wind tunnel experiments are being undertaken to understand the prevailing transition mechanisms with and without the presence of incoming wakes. The ultimate aim is to use the knowledge gained from this work to aid efficient blade designs.

Faculty

Axial compressors

Axial compressors in gas turbines and aeroengines suffer from rotating stall at low mass flow and can cause a catastrophic drop in pressure ratio. Stall margin improvement studies investigate ways to enhance the ‘stability range’ either through active or passive means so that the engine can operate safely throughout its mission cycle.” Dr Vasudevan Kanjirakkad

Senior Lecturer in Experimental Thermofluid Mechanics

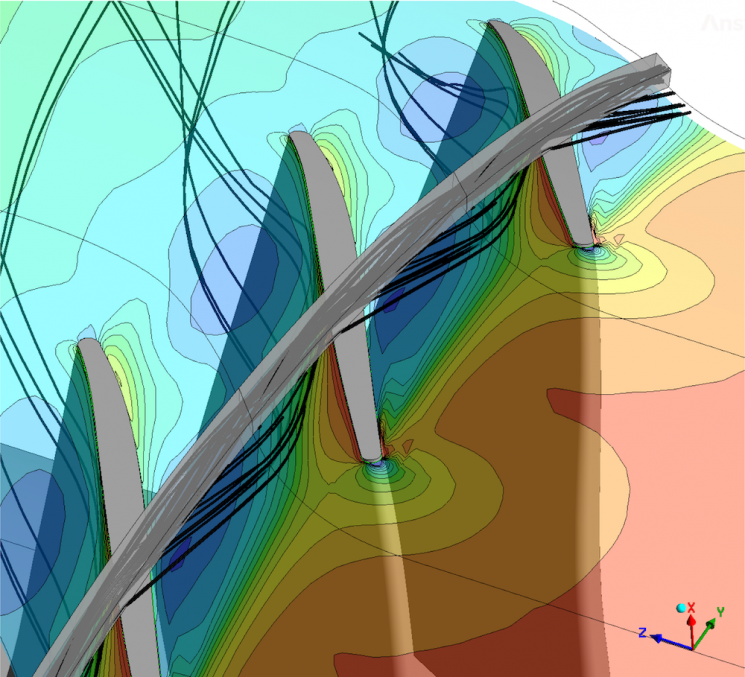

Rotating stall results from an instability of the compression stage or blade row at flow rates below a critical value (peculiar to each compressor). It is usually caused by a build-up of blockage within the blade passage. In many compressors, the rotor blade tip area can develop regions of low momentum fluid, or blockage, caused by tip leakage flow or vortex. This happens as the compressor pressure increases and the mass flow decreases during operation. It is possible to alleviate the blockage by implementing active or passive casing treatment features.

In the present study, the use of optimised circumferential grooves (due to their simplicity) is explored for improving ‘stall margin’, i.e., to extend safe operability of the compressor to lower mass flow regimes while still producing useful pressure rise. The optimisation is conducted using a physics-based parameter with the aid of machine learning tools. Both experimental and computational work is undertaken to understand the physics and to validate the concept.

Faculty

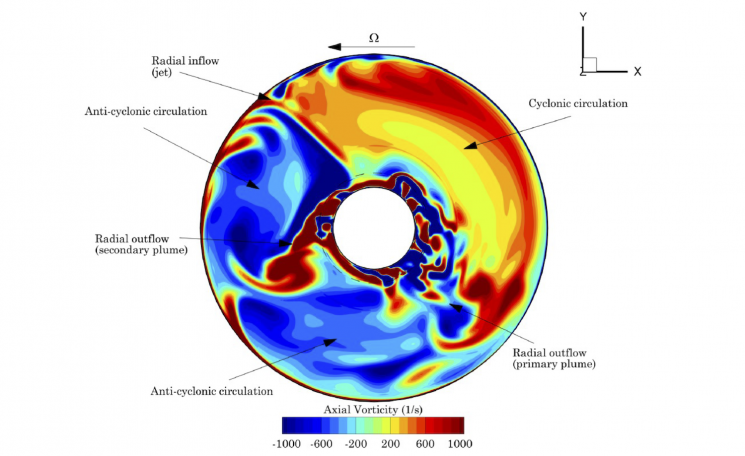

Rotating cavities

The rotating cavities are critical to the functioning of modern gas turbines but also pose a direct parasitic loss to efficiency. Minimising these losses through physical understanding and modelling is crucial to meeting net-zero aviation goals and is also opening new avenues of research in electric motor cooling.” DR MARK PUTTOCK-BROWN

Senior Lecturer in Mechanical Engineering

The flow structure and heat transfer interactions within rotating cavities in gas turbines provide a particularly complex problem and has been studied for several decades. Whilst a mature research field, the convergence of both accessible high-performance computational resources and advanced experimental techniques means we have the tools to make significant advances in our understanding of the physics of these systems. These advances allow the development and validation of accurate digital tools used by industry to design the next generation of engines whilst reducing the associated lead-times and number of costly full-engine tests.

The EMERC is home to one of only three active experimental facilities in the world capable of producing the engine like test conditions within a laboratory. As a laboratory scale experiment, it is possible for us instrument and measure more than what is possible with an engine, allowing us to probe in ever more detail the complexities of this phenomena.

Faculty

Rotor-stator cavity and rim-seals

Ingestion of gas from the hot turbine passages into the rotor-stator cavity can have catastrophic effects on the engine as it impacts the thermo-mechanical growth, and the thermal integrity of the discs & the blades mounted on them. Our research on sealing and aero-thermal interactions aided by world-leading test facilities and computational tools continues to help aero/gas-turbine engine manufacturers to design safe and efficient engines of the future.” Dr Vasudevan Kanjirakkad

Senior Lecturer in Experimental Thermofluid Mechanics

A well-designed rim-seal and an ideal amount of purge air is essential, but the complex geometries involved and the range of working conditions that the engine operates through any single mission makes the aero-thermal management of the wheel-space difficult. We employ unique engine-realistic experimental rigs with high-density instrumentation and numerical modelling to understand the prevalent physics and to arrive at optimal sealing solutions. The high-quality test data that we produce is also useful in creating or calibrating reduced order analytical models that aid fast and accurate design and analysis of related components.

The current research looks at the cavity aerothermal behaviour and the effects of its interaction with the turbine stage for a range of purge-flow condition.