Facilities and expertise

Learn more about the facilities and equipment we use in the Energy and Materials Engineering research centre.

Sussex Energy Research facility

We have a solar powered (Net Zero) battery laboratory that provides a safe test environment for battery testing. We can characterise battery cells, investigate new charging and discharging strategies, develop battery cooling approaches and develop battery management systems.

Experimental expertise

Our expertise allows us to measure temperature, pressure, mass-flow rate and velocity within a wide range of applications.

- Laser Doppler Anemometry

Two Component LDA System: 5 W Argon - Ion Laser, Dantec Burst Spectrum Analyser, Bragg Cell giving a 40 MHz frequency shift, optical fibre connections to a 100, 200 or 250 mm focal length probe. Operation in either back scatter or off axis (e.g. side scatter), 3-D precision computer controlled traverse system, Pockels cell and delay generator to allow synchronised shuttering of beams to external events.

- Particle Image Velocimetry

New Wave, 120 mJ, Nd:YAg Laser, One pair of 2 Mega pixel CCD cameras and Scheimpflug camera mounts to allow for 3D steroscopic PIV measurements, Laser and camera endoscopes for limited access, a range of focal length lenses for the CCD cameras.

- Thermal Imaging and Pyrometry

FLIR Thermovision A20 Imaging System

Full field non-invasive temperature measurement

Temp range: -20 to 250 °C

Spectral range: 7.5 to 13 μm

LAND Instruments System 4 M3 Fibre Optic Thermometer

The use of a fibre optic light guide allows the detector and electronics enclosure to be located in a less hostile environment and enables access to difficult targets.

Temp range: 50 to 250 °C

Spectral response: 2.3 μm

IMPAC Infrared IGA 140

A highly accurate digital pyrometer with focusable optics for non-contact temperature measurements on metals, ceramics and graphite etc

Temp range: 300 to 1300 ºC

Spectral response: 1.45 to 1.8 μm

IMPAC Infrared IN3000

Small, stationary infrared thermometer for non-contact temperature measurement.

Temp range: 0 to 300 ºC

Spectral response: 8 to 14 μm

- Mechanical Workshop

The University of Sussex has comprehensive in-house Mechanical Workshop facilities furnished with modern automated and conventional plant and equipment plus full welding capabilities. These facilities are complemented by a number of full time engineering technicians most of whom are former toolmakers with a wealth of experience in most aspects of mechanical engineering. Our engineers are familiar with machining specialist materials such as Titanium, Nimonic and other aviation alloys.

Plant list

CNC Mill x 2 (Bridgeport type)

CNC Lathe

CNC 4 axis Wire EDM

Numerous conventional machinery.

Capacity

Turn: up to 1200 mm diameter

Mill: up to 1000 mm x 350 mm

In addition to in-house facilities the department maintains close links with several precision and specialised sub contractors.

- Hot Wire Anemometry

Dantec 6 channel Stream Line constant temperature anemometry system, velocity calibration unit, various probes.

- Temperature and Pressure Measurement

Temperature and Pressure Calibration Equipment

Gallium cell, water triple point cell, Isotech oil bath, water bath, distilled water maker, ice baths, distilled water ice maker, traceable PRTs, dead weight tester, Druck calibrators.

Temperature and Pressure Instrumentation

Extensive experience in the manufacture, calibration and installation of thermocouples and pressure transducers. Druck and Kulite pressure transducers, static pressure tappings, yaw probes, pressure rakes, total temperature rakes.

- Air Supplies

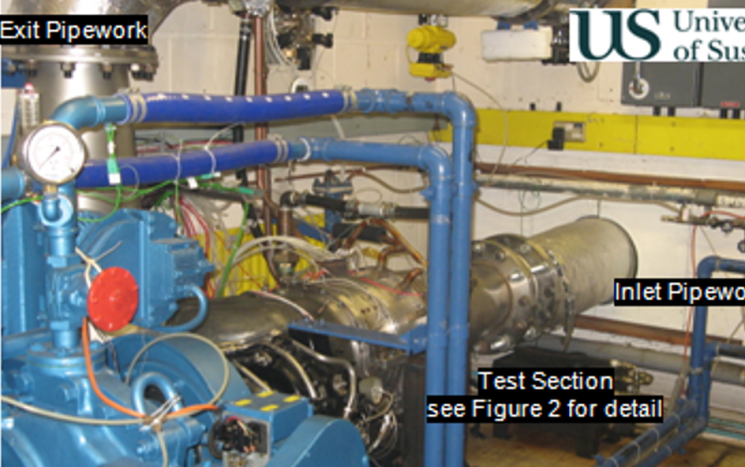

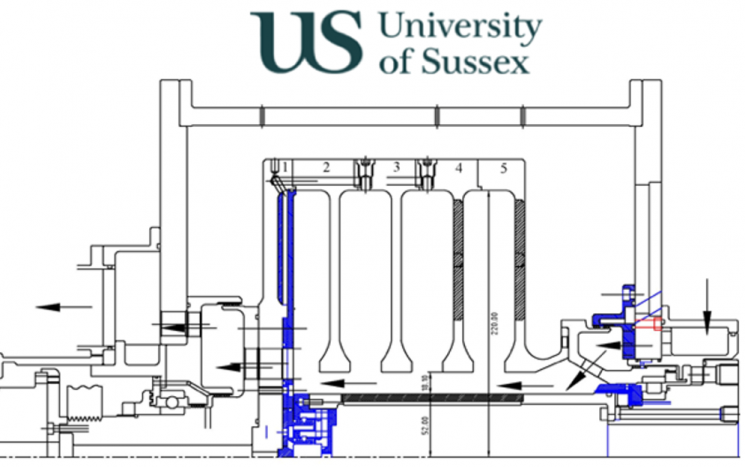

DART air supply

A Rolls-Royce DART gas turbine engine has been installed in the TFMRC driving a centrifugal compressor to provide a flow of up to 10 kg/s at conditions up to 3.0 bara and 150 °C.

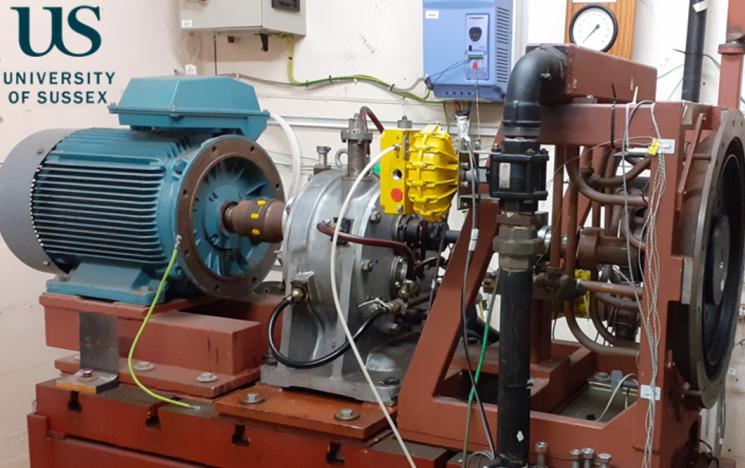

Compressors

Atlas CopCo Air Supplies: An Atlas Z250 compressor (0.8 kg/s, 7.5 bar) and a Z110 (0.5 kg/s, 7.5 bar) cooled and dried air supply provide independent internal air supply.

Hydrovane: 0.1 kg/s, 7.5 bar.

Numerical expertise

For numerical modelling we have a large share of the high-performance computing facilities of the University.

We have developed a number of in-house CFD codes, which are the main research tools for numerical studies. Commercial software such as ANSYS is also used for research and within teaching and Year 3, and MSc and MEng student projects.