Measuring harmful emissions from resin-based 3D printers

- Measuring emissions from 3D printers (text version)

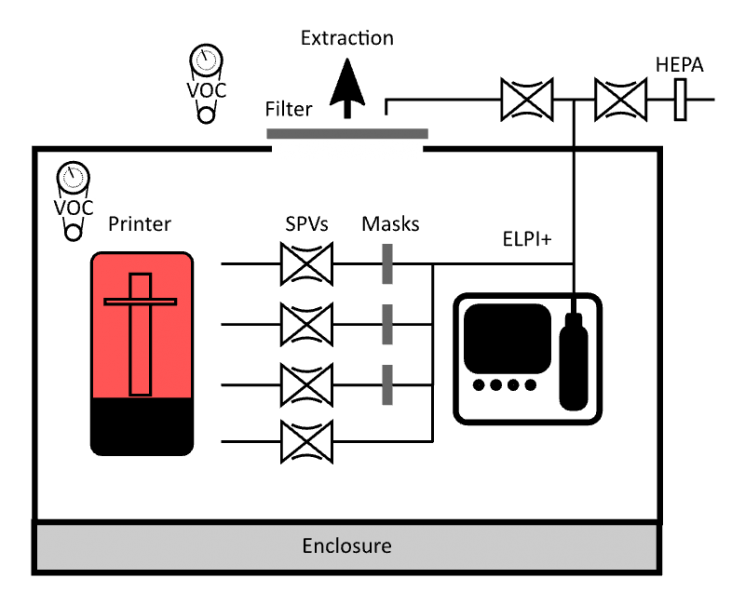

The 3D printer is placed within a enclosure and a series of valves and masks, connected to an ELPI+ analyzer, enable real-time aerosol measurements to be made.

Measuring and mitigating the risks posed by emission from resin printers will allow us to protect users, develop innovative solutions and inform sensible health and safety policies.” Dr Henry Dore

Research Fellow within the TFMRC

3D printing has revolutionized materials production with 3D printers found in homes, businesses, and universities across the country. Second generation 3D printers use liquid resin that is cured into 3D structures by ultraviolet light. Although these resin printers were initially expensive tools used mostly in biomedical applications such as dentistry, new low-cost resin printers are now readily available.

Aerosols and volatile organic compounds are produced when using resin 3D printers (in the range of 41 to 45 nm and 161 to 322 mg/g printed respectively), but current health and safety guidelines are based largely on limited studies and ultimately the responsibility for the correct use of PPE lies with the end user.

At the TFMRC we evaluate device emissions using high-resolution low-pressure particle impactor technology. This separates particle emissions by size, as well as generating real time data on particle quantity and mass at the nanometre scale. This platform also isolates samples for advanced chemical analysis and profiling. TFMRC has a bespoke evaluation chamber where we can measure second generation 3D printer emissions in a controlled environment.

Through defining the mixture of pollutants generated during 3D printing we will develop novel interventions and technologies to address these emissions, as well as formulating informed health and safety policies.