Stranger things

Nanotechnology has the potential to make radical differences to everyday lives and, in some circumstances, save them. Professor of Materials Physics at Sussex Alan Dalton explains how.

The nanotechnology revolution

At the start of the 21st century, scientists were predicting that nanotechnology – the manipulation of materials at an atomic level – would revolutionise our daily lives. From miniaturised devices to virtually unbreakable materials, science fiction was about to become reality. And at the forefront was the University of Sussex.

The late Sir Harry Kroto was a Professor of Chemistry at Sussex who received the Nobel Prize in 1996 for the discovery of a form of carbon (named the C60 Buckminsterfullerene) that could be a building block for super-strong and highly conductible ‘nanotubes’. Today, Professor Alan Dalton, who joined the University in 2016 largely because of Kroto’s groundbreaking work, is taking that legacy forward.

Professor Dalton and his team are among those developing practical and affordable applications for nanotubes that really will change our lives – and, in some circumstances, save them. Their projects include smart clothing that can detect an array of bodily functions, virtually indestructible yet incredibly thin smart screens and nanobarcoding for food packaging to ensure food safety.

Alan, who has two decades of experience in nanotechnology, says: “We are working with building blocks that are 50,000 times smaller than a single human hair. The real step change is in how we are now able to see them and manipulate them with the aid of atomic-force microscopes and electron microscopes.”

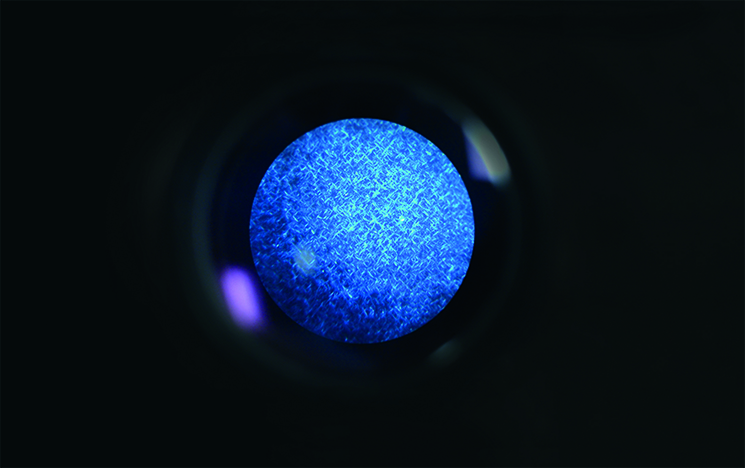

One such nanomaterial is graphene, a honeycomb lattice form of carbon derived from graphite (the ‘lead’ in pencils). First observed in 1962, it was finally produced in 2004 by physicists Konstantin Novoselov and Andre Geim, who received the Nobel Prize for their work in 2010.

Although it consists of just a single layer of atoms, effectively making it a 2D nanomaterial, graphene has extraordinary properties in terms of strength (it is 400 times stronger than steel), transparency and electrical conductivity. The idea for a simple, wearable but wireless device made from graphene that could detect pulse and respiration rates came to Alan while making French salad dressing with his nineyear- old daughter.

“She was amazed to see the little circle particles of oil,” he remembers. “And it set me thinking about how we could use the principle to create emulsions in which tiny balls of graphene are suspended in oil and water.”

Experimentation led to the emulsion being incorporated into a fabric that, when stretched, changes conductivity. If turned into a simple skin patch, which expands and contracts with each breath or heartbeat, it could have a variety of potentially life-saving applications.

We are working with building blocks that are 50,000 times smaller than a single human hair.”Professor Alan Dalton

Materials Physics at Sussex

“A simple and cheap-to-produce sensor like this could help prevent neo-natal deaths in remote communities in developing countries,” says Alan, with reference to a proposed trafficlight system, which tells a parent when their child is unwell or relays the information to a hospital.

“It could also be used for dementia patients to detect dehydration, a common problem with the elderly, and remind them to have something to drink,” he adds.

Another project being developed by his team is a food packaging material containing a graphene polymer hybrid that will change colour after a certain time period or with variations in temperature. “Perishable foods and medications that have limited lifespans, or need to be kept at a particular temperature, can cause logistical issues for manufacturers and suppliers,” he explains. “Penicillin, in particular, must be kept below a certain temperature. If it’s being sent to a war zone, aid workers need to know that what they are administering is going to work. This could solve this challenge.”

Likewise, Alan and his colleagues are currently working to develop nanobarcoding for supply chain management. “Customers want to be assured that food has been stored correctly. These simple little indicators are almost impossible to counterfeit.”

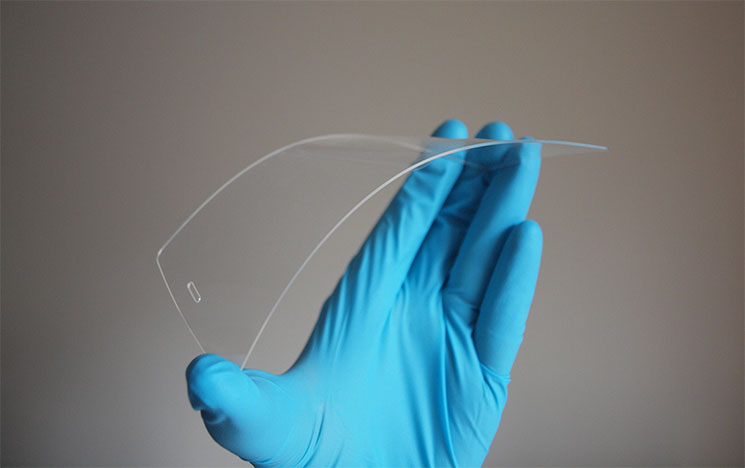

Graphene’s extraordinary strength and flexibility has led to perhaps the most eagerly awaited of the team’s projects. Using silver nanowires and graphene, they have produced a screen that’s more flexible – and hence less breakable – than the currently available technology. The material also has eco and cost benefits. At the moment, touchscreens are made from a rare, mined metal called indium tin oxide, supplies of which are expected to be exhausted in just a few decades.

“There needs to be a new disruptor technology, and this nano graphene system could be that,” says Alan. “These screens will be very cheap to produce as there is a plentiful supply of graphite and silver.”

A further blue-sky area of research is megastructure live monitoring. Bridges, oil pipelines and container ships are subject to nano level material faults and recognising these early offers the potential to prevent environmental disasters like the Exxon Valdez oil tanker spillage in Alaska in 1989.

The continuing challenge for Alan is to create technology that will be both commercially viable and have a positive impact on the world and society. As he points out: “There are severe problems in the world – water shortages, energy demands, healthcare – and universities are in a position to help find the solutions.”

Alan and his team are now collaborating with Advanced Material Development, a privately funded commercial business formed to support scientific research in British universities to take these ideas to the next stage. “We have a real issue with taking our great ideas and transitioning them into the market place,” he says, “so this is a really exciting opportunity for us because it’s the first time in my career that I have been able to work with a company that sees the pathway to bring it from the lab into an industrial environment and actually make a difference.”